Advantages Of Using Laser Cutting

If you work within the manufacturing industry, then you know how hard this kind of industry can be to work in. So, when something can make your life easier when you are on the job, it is a welcome tool in your toolbox. Laser cutting is one of those things that can make your projects much easier and faster, meaning that it can be better than traditional cutting methods. Below is a guide to laser cutting and an explanation of why it is so useful, as well as some of the other advantages that come with it.

They Are Very Precise and Accurate

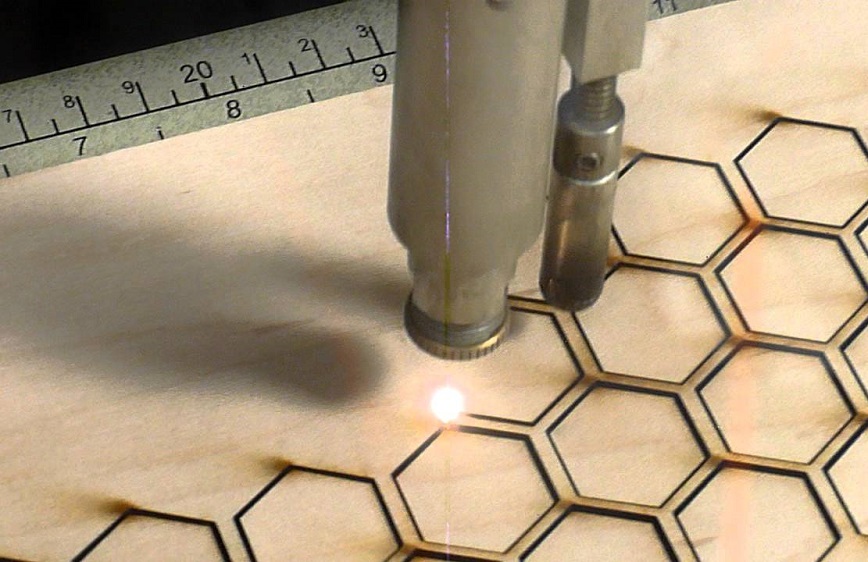

When you cut with lasers, you use a tool that is extremely small yet very powerful at the same time. The laser in the machine shoots a very focused beam of light through the material you are working with, so as to cut it with extreme precision. The laser is so powerful that it can melt or cut through even the most durable of materials with accuracy that you cannot get with anything else.

They Are an Economical Tool

One of the biggest benefits of using this type of cutter is that it is very economical and can save you a lot of money. It ends up saving you money because you do not have to get custom tools for your project and it also does not wear out after usage. All you need to do is load the blueprint and let the computer and laser do the work for you. They also have very few moving parts or additional parts that need to be replaced. This means it saves you money when it comes to maintenance and operating costs.

It Can Handle Even The Most Complex Project

When it comes to giving your new laser cutter a pattern to cut out, you cannot give it one that is too hard or complex to take on. With a schematic that is correct and detailed, it can quickly and easily create an end-result from your project that is simple and straightforward or as complex as projects come. Even when extremely complex the laser will cut through your materials with unmatched precision that no other tool can do and can tolerate just about any material over and over again.

It Reduces Waste

Another great thing about using a laser is that it can use just about the whole part of the material it is cutting out. This means that a laser can maximize how much of the material can be used so it will help lower the cost of your project, allow you to complete the project faster, and cuts down on how much of the raw material goes to waste during the cutting process.

They Don’t Damage or Warp Materials

Many people think that since lasers are so hot and focused, they will cause the material you are cutting to get warped or distorted. However, the actual laser is actually very small which means that it generally causes no damage or other issues to your materials. It also cuts so quickly that it does not give the material that it is cutting a chance to become too hot and warp while being cut. It is precise right down to a science so the integrity of your materials is not lost and you instead end up with a finished product that is perfectly precise and just how you want it to look every single time.