Learn Everything About Industrial Filtration In Detail

We have already learned a lot about the process of filtration and its significance in our science books. This process can be helpful in a lot of ways, especially for industrial purposes. Filtration is such a process that can remove all the suspended solid particles. You can remove them from fluids and gasses. This filtration process works through a medium called a filter that works like a strainer. The filtration process is significant for the removal of impurities from water. You get the supply of this filtrated water all over the city. Since it has so many applications, industrial filtration is quite significant.

Applications of Industrial Filtration

To carry out different filtration processes in an industrial area, you need filtration equipment as well. There are many applications of filtration that industries carry out. These filtration applications are quite common. Let us go through some of these applications of industrial filtration and explain them in detail.

Protecting the industrial equipment: There are many expensive types of machinery that different industries use for the manufacturing process. So, there is a need to protect them. Otherwise, they can damage everything. Filtration prevents this damage from happening and protects it.

Prevention of Contamination: This also means maintaining safety and environmental issues in the industry. Filtration can help you to remove contamination and health hazards. Filtration improves the quality of the products.

Purification: The filtration process can help clean water, pharmaceuticals, and chemicals from industries. So, it can eliminate sand, sediment, gravel, and many other particles from industrial products.

Isolation of the product: If you need to separate industrial processes from oil, water, solids, gasses, and other fluids, thus isolating them. This can make every system function properly.

The efficiency of operations: You would want all the industrial operations to run efficiently and smoothly. With the process of filtration, industrial companies can save time and make every process quite efficient as well.

Read more: Spot Factoring VS Selective Factoring

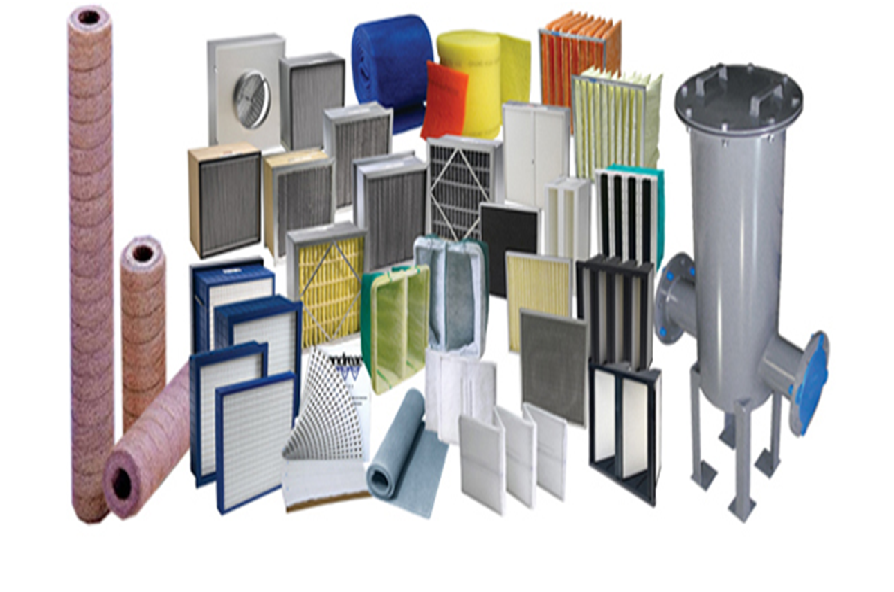

Types of Industrial Filtration

There are many types of filtration required for industrial processes. Some of these are very significant to carry out industrial processes are:

- Gravity filtration

- Centrifugal filtration

- Cold filtration

- Vacuum filtration

- Hot filtration

- Mechanical filtration

- Multi-layer filtration

Where can you use Industrial filtration?

Industrial filtration is a technology that is used on the floors of chemical industries, Oil and gas industries, Automobile industries, Ceramic, Electronics, Mining, power plant industries, refineries industry, and water treatment industry.

Read more: How to Build a Successful ERM Program?

Not only the floors, but filtration is also carried on different parts of the industry. It plays a major role in cleaning and separating impurities to obtain high-quality industrial products.